For FDM 3D printer users, slicing models into Gcode is a necessary and important step in 3D printing. Well-considered slicing settings can help us reduce printing time, save material, and most importantly, increase the chance of successful printing. In other words, we need to set up some parameters in slicing software to get the desired results we hope for.

Cura 3d Printer Settings

Slicing Software

Cura Jerk Settings: Enable Jerk Control. 3D printers come with a firmware jerk setting. Usually, this setting is high implying a minimum jerk. As a rule, however, Cura software settings override firmware settings. Cura jerk settings decrease the speed settings of the firmware. This makes the printing slower but increases print quality and accuracy. Clevenger23 wrote: couple of questions before i get to testing later today, maybe you can assist me with first. I notice you have the X Min at -10 but with Cura 4.5 it will not go less than -20. The rest of the settings are okay, also when i set up cura by XYZ's instructions, it defaults the print speed to 60mm/s i will attach a couple of pictures.

There are many slicing software on the internet. Some software is free while some need to be paid for. Some are simple and easy to use while some have more advanced functions. There is always one option fit for you.

Here are several Common slicing software people often use.

Cura

Cura is a free and open-source slicer developed by Ultimaker. It's compatible with all of the common FDM 3D printers and it's very friendly to beginner.

Simplify3D

Simplify3D is a paid slicer. It has a user-friendly interface but also gives the users much space for modification and customization. One of its advantages is editing and repairing complex 3D models.

Slic3r

Simplify3D is a paid slicer. It has a user-friendly interface but also gives the users much space for modification and customization. One of its advantages is editing and repairing complex 3D models.

Slic3r

Slic3r is another free and open-source slicer. It has some advanced slicing features including honeycomb infill, splitting models into parts, and so on.

Other slicer or software are well used by 3D printer users, like KISSlicer, OctoPrint and Creality Slicer. Each slicer has its special features and It's hard to tell one is better than another. Here, we will Use Cura as an essential tool for our 3D printing as it's free, easy to get hands-on and able to help us have a better understanding of 3D printer.

Cura 4.6

As a free, open-sourced slicing tool, Cura is very friendly to 3D printer users. If you are still new to FDM 3D printing and just got your first 3D printer, Cura maybe the easiest tool to use for simple slicing. As we can see from its operation interface, each icon/option is placed clear and convenient for users.

Now, Let's see How simple to use Cura.

Simple Slicing Steps

After we install and open Cura, we need to follow these steps to transform a 3D model into a machine lauguage(Gcode). See search com.

- Let the slicer know what type of printer we use for printing. you can add your printers from an offered list or custom your DIY printer setting; We also need to define what material and nozzle size the printer use. These settings are very basic but important for successful prints.

- Import 3D models. we can import one or multiple models for one print. Cura supports a variety of file formats, not only includes common 3D formats like STL, OBJ but also picture files such as JPG and PNG.

3. There is a list of tools allow us to edit models, although their functions are limited to 'move', 'scale' and other simple commands.

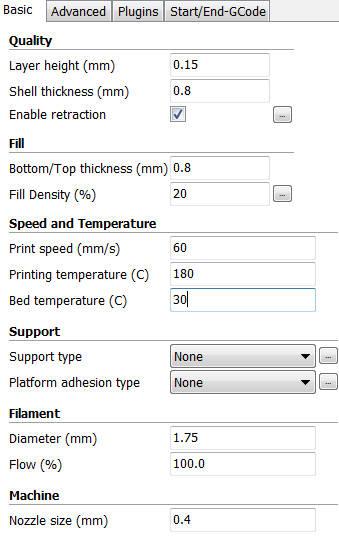

4. For beginners, Cura provides an easy-to-follow slicing setting. We only need to define the print quality( smaller number, better quality, longer printing time), infill( more infill, more weight, longer time), support(some overhanging parts need support material) and adhesion( add it to let models stick on hotbed).

5. Slice and save Gcode. After 'Slice', we can preview the edited models layer by layer. It's a good chance to review the models and settings before we print. By doing so, we could find some errors or Inappropriate settings like long time printing or too much material would be used. We can always go back and modify the settings.

Now, Cura has generated a Gcode file which can be save to a SD card and read by a 3D printer.

Conclusion

Cura has many more advanced functions that allow us to optimize the slicing process and they could be complicated. But Cura also offers these easy-to-follow slicing settings for new users to let us print objects without any obstacles.

Cura 3d Printer Software

Since xyzPrinting updated their firmware to make all my 3rd party tags useless and also enabled direct printing through the USB port I thought it might be useful to share the settings for my da Vinci Mini W+ printer that work. They should form the basis for other printer models.

These settings are for black PLA material, firmware version 1.2.0 and Cura 4.4.1

The profile settings are based on Custom FFF printer, generic PLA and Normal print quality.

Machine settings:

Printer settings

X (width) 150mm

Y (depth) 150mm

Z (height) 150mm

Build plate shape Rectangular

G code flavour Marlin

Printhead settings

X Min -10mm

Y Min -10mm

X Max 10mm

Y Max 10mm

Gantry height 100mm

Extruder settings

Nozzle size 0.4mm

Compatible material size 1.75mm

Start G-code:

G28 ;Home

G1 Z15.0 F6000 ;Move the platform down 15mm

;Prime the extruder

G92 E0

G1 F200 E3

G92 E0 Cookie animal crossing new leaf.

End G-code:

M104 S0

M140 S0

;Retract the filament

G92 E1

G1 E-1 F300

G28 X0 Y0

;Move gantry and print bed to allow access to completed print

G1 Z100 F1200; Move gantry up 100mm

G1 Y8 F1200; Move print bed out 80mm

M84

Print settings:

Quality

Layer height 0.2mm

Initial layer height 0.3mm

Shell

Wall thickness 0.8mm (could increase to 1.2mm if needed)

Top/bottom thickness 1.0mm

Free 3d Prints For Cura

Infill

Density 10% (can go up to 25% if additional strength needed)

Infill pattern Grid (default in cura but I have also used lines)

Material

Printing temp 200 deg (Cura monitor shows an actual temp of 203 deg)

Morphvox pro autotune. Flow 100% (default value. Some prints and/or printers may need a higher value)

Retraction distance 4.0mm

Retraction speed 30mm/sec

Speed

Print speed 40mm/sec (Cura will calculate the rest and these are OK so far)

Build pattern adhesion

Type Skirt

Line Count 15

Distance 0.01mm

This produces a skirt that acts very much like a brim but I have found that it is easier to clean up afterwards (it just snaps off). The Mini W+ print bed is unheated so it really needs this to aid adhesion. I also use blue printers tape and glue stick. So far so good!

Cura 3d Printer

So. Do these settings print a 3D Benchy??? Hell yeah!!!!

I am now back up and running on 3rd party PLA with no tags. (Interesting point to note though that if you leave a tag on the printer the spool length will still be updated as you print). The only operations I am still using the xyzPrint software for is loading/unloading filament and cleaning the printhead. As soon as I can work out the G-code for that and how to send it to the printer I will be free of that too.